Product Description:

The SAE 100R2 / EN 853 2SN hydraulic hose is built for durability and consistent performance in heavy-duty hydraulic systems. It features an oil-resistant synthetic rubber inner tube, two layers of high-tensile steel wire braid reinforcement, and a weather- and abrasion-resistant outer cover. With its combination of strength, flexibility, and resistance to harsh environments, this hose ensures reliable performance and long service life in both mobile and stationary equipment.

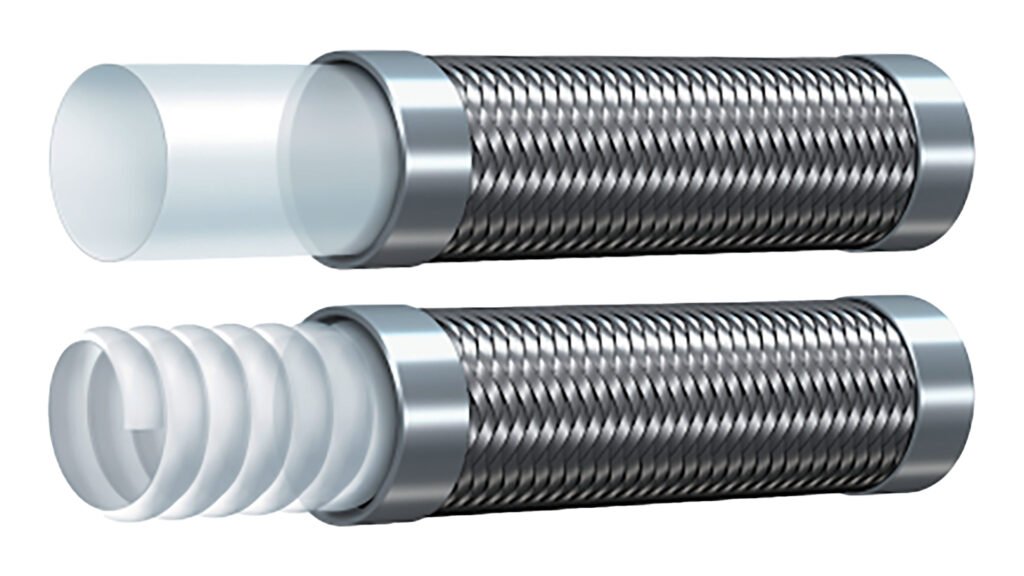

Construction:

Tube:

oil-resistant synthetic rubber

Reinforcement:

two steel wire braids

Cover:

oil, water, heat, abrasion, weather, and ozone-resistant synthetic rubber

Temperature Range:

-40°C to +100°C (-40°F to +212°F), intermittent up to +125°C (+257°F)

Applications:

SAE 100R2AT / EN 853 2SN hydraulic hose is suitable for medium to high-pressure hydraulic systems handling petroleum-based or water-based fluids, lubricating oils, diesel, and mineral oils. It is widely used in construction equipment, agricultural machinery, mining operations, oilfield equipment, and industrial hydraulics, ensuring safe and efficient fluid transfer under severe environmental and abrasion conditions.

Key Features:

Two layers of high-tensile steel wire braid reinforcement

• Oil and weather resistant synthetic rubber cover

• Excellent flexibility and abrasion resistance

• Temperature range: -40°C to +100°C (-40°F to +212°F)

• Fully meets SAE 100R2AT and EN 853 2SN standards

• Tested for impulse resistance and sealing reliability

• Available with various fittings and coupling assemblies

TECHNICAL DATA

| Part Number | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| dash | DN | inch | Min ID | Max ID | Min OD | Max OD | MPa | bar | psi | MPa | bar | psi | mm | inch | kg/m | lb/ft | |||||

| mm | inch | mm | inch | mm | inch | mm | inch | ||||||||||||||

| YH-R2-03 | -3 | 5 | 3/16” | 4.6 | 0.18 | 5.4 | 0.21 | none | none | 14.1 | 0.56 | 41.5 | 415 | 6,010 | 165.0 | 1,650 | 23,900 | 90 | 3.54 | 0.210 | 0.14 |

| YH-R2-04 | -4 | 6 | 1/4” | 6.2 | 0.24 | 7.0 | 0.28 | none | none | 15.7 | 0.62 | 40.0 | 400 | 5,800 | 160.0 | 1,600 | 23,200 | 100 | 3.94 | 0.215 | 0.14 |

| YH-R2-05 | -5 | 8 | 5/16” | 7.7 | 0.30 | 8.5 | 0.33 | none | none | 17.3 | 0.68 | 35.0 | 350 | 5,070 | 140.0 | 1,400 | 20,300 | 115 | 4.53 | 0.260 | 0.17 |

| YH-R2-06 | -6 | 10 | 3/8” | 9.3 | 0.37 | 10.1 | 0.40 | none | none | 19.7 | 0.78 | 33.0 | 330 | 4,780 | 132.0 | 1,320 | 19,100 | 125 | 4.92 | 0.320 | 0.22 |

| YH-R2-08 | -8 | 12 | 1/2” | 12.3 | 0.48 | 13.5 | 0.53 | none | none | 23.1 | 0.91 | 27.5 | 275 | 3,980 | 110.0 | 1,100 | 16,000 | 180 | 7.09 | 0.400 | 0.27 |

| YH-R2-10 | -10 | 16 | 5/8” | 15.5 | 0.61 | 16.7 | 0.66 | none | none | 26.3 | 1.04 | 25.0 | 250 | 3,620 | 100.0 | 1,000 | 14,500 | 205 | 8.07 | 0.480 | 0.32 |

| YH-R2-12 | -12 | 19 | 3/4” | 18.6 | 0.73 | 19.8 | 0.78 | none | none | 30.2 | 1.19 | 21.5 | 215 | 3,110 | 86.0 | 860 | 12,500 | 240 | 9.45 | 0.600 | 0.40 |

| YH-R2-16 | -16 | 25 | 1” | 25.0 | 0.98 | 26.4 | 1.04 | none | none | 38.9 | 1.53 | 16.5 | 165 | 2,390 | 65.0 | 650 | 9,400 | 300 | 11.81 | 0.910 | 0.61 |

| YH-R2-20 | -20 | 32 | 1-1/4” | 31.4 | 1.24 | 33.0 | 1.30 | none | none | 49.6 | 1.95 | 12.5 | 125 | 1,810 | 50.0 | 500 | 7,300 | 420 | 16.54 | 1.243 | 0.84 |

| YH-R2-24 | -24 | 38 | 1-1/2” | 37.7 | 1.48 | 39.3 | 1.55 | none | none | 56.0 | 2.20 | 9.0 | 90 | 1,300 | 36.0 | 360 | 5,200 | 500 | 19.69 | 1.450 | 0.97 |

| YH-R2-32 | -32 | 51 | 2” | 50.4 | 1.98 | 52.0 | 2.05 | none | none | 68.6 | 2.70 | 8.0 | 80 | 1,160 | 32.0 | 320 | 4,600 | 630 | 24.80 | 2.050 | 1.38 |

| YH-R2-40 | -40 | 63 | 2-1/2” | 63.1 | 2.48 | 65.1 | 2.56 | none | none | 81.8 | 3.22 | 7.0 | 70 | 1,010 | 28.0 | 280 | 4,100 | 760 | 29.92 | 3.962 | 2.66 |